Your bathroom floor has a shower pan that is waterproof and collects water then directs it to the drain. The shower pan needs to be installed correctly to support the weight of the users and keep the underlying layers from damage by the water. The right mortar mix for the shower pan determines how good the pan will be. If you make a mistake with this one, you risk destroying the whole shower floor.

The best mortar for shower pans is a mixture of sand and Portland cement, creating a water-resistant barrier that can support the weight of the shower unit and its users. You can create your own with Portland cement and fine sand (1:5) and 4 quarts water for 80 lb. of the mixture.

What mortar to use for a shower pan

Mortar is preferred for shower pans over other options such as concrete and cement given that it bonds better to other surfaces and is more moldable. The best mortar mix for shower pans contains sand and Portland cement. This will create a water-resistant barrier that will support the weight of the shower floor and its users.

| Types of Mortar | Ingredients |

| Quikrete Floor Mud | Portland cement, graded sand, other components |

| Quikrete Sand/Topping Mix | Portland cement, commercial grade sand, other ingredients |

| Sakrete Sand Mix | Portland cement, concrete sand |

| DIY Shower Pan Mortar Bed | Portland cement, fine sand |

There are three main types of mortar for shower pans as follows:

1. Quikrete Floor Mud

The Quikrete Floor Mud is a concrete mix manufactured by QUIKRETE, which is ready to create shower pans, slate, travertine, and marble floor tiles. When mixed with water, it creates a smooth and water-resistant surface ideal for shower pans.

Since they have been calculated for you, you don’t need to calculate any of the ingredients with the Quikrete mortar mix for shower pans. Just pour the mix into a container, then add water (4 quarts for each 80 lb. bag) before applying it to the shower floor.

The benefits of using Quikrete Floor Mud include the fact that you can use it both indoors and outdoors, you don’t need to calculate the parts, it provides a strong result (5000 psi compressive strength once fully cured), and it is easy to form the desired shape of the floor. The only downside is that it’s not easily available.

How long should mud bed cure before tiling?

A mud bed needs to be cured for at least 28 days before tiling. This ensures that it’s waterproof and has the required compressive strength to retain its shape and integrity when in use.

How many bags of mortar for the shower pan?

It depends on the size of the shower floor. It will be enough if the floor has between 2 and 3 inches of thickness at the thickest places and at least 2 inches of thickness at the thinnest.

2. Quikrete Sand/Topping Mix

This sand topping mix for shower pans, also by Quikrete, is made from a mix of Portland cement, commercial-grade sands, and other components. Unlike Quikrete Floor Mud, whose ingredients are consistent, the amount of water needed for the Quikrete Sand/Topping Mix depends on the components used to form it. The manufacturer will always indicate that on the bags.

3. Sakrete Sand Mix

Sakrete Sand Mix is made of Portland cement and concrete sand and is a popular alternative to the above options from Quikrete. Besides the shower pan, it can be used for walks, steps, and leveling floors both indoors and outdoors.

4. DIY Shower Pan Mortar Bed

You can mix your shower pan concrete using sand, cement, and water. Mix 1 part of Portland cement with 5 parts of fine sand. For every 80 lbs. of this mix, add 4 quarts of water.

Your own shower base mortar might seem like a cheaper option, but it’s usually not as good as the commercial alternatives. Both Quikrete Floor Mud and Quikrete Sand/Topping Mix don’t cost much, yet they’re easier to work with and provide better results than DIY options.

Shower pan mortar consistency

All the shower floor mortar mixes above must have the same consistency to obtain the best results. Once mixed, you should be able to form a ball with the mix in your palm. The ball should hold its shape but release some water when squeezed.

If the ball collapses, it’s too wet, and you should add more of the dry mix. If it retains its shape but doesn’t release water when squeezed or crumbles apart, it’s too dry and needs more water to be added.

Shower pan mixes: comparison

| Quikrete Floor Mud | Quikrete Sand/Topping Mix |

| Affordable – $7 per 80-pound bag | Slightly costlier – $8 per 80-pound bag |

| A bit hard to find | Easily available |

| Available in 80 lb. bags | Available in bags of 10, 40, 60, and 80 pounds |

| Easy to use | Easy to use |

Shower pan material

Once you lay the mortar bed for your shower, the shower pan you install on top can be made from the following materials:

Acrylic

An acrylic shower pan is made from modified plastic under pressure and heat to form a piece large enough to fit your bathroom floor.

Tile

While tile is highly attractive, it also requires a lot of skill and care to ensure it provides a waterproof seal for the rest of the floor. It also requires maintenance regularly to maintain its integrity. When installing tiles as the shower pan, ensure the mortar bed is at least 2 inches thick on the outer edges of the floor, and reduces towards the shower drain to allow water to flow.

Fiberglass

Fiberglass shower pans are created from polymer reins strengthened with woven glass fibers. Although cheaper than the alternatives, they’re more likely to get scratches and stains.

Composite materials

A combination of different materials can be used to create a shower pan whose qualities will depend on the materials used. For example, acrylic can be strengthened with fiberglass to make a better shower pan than the individual materials.

For the preformed shower pans made from fiberglass, acrylic, and composite materials, the manufacturer needs to provide the thickness needed for the pan to perform correctly.

When installing all of these shower pans, follow the EPA’s guidelines on moisture control on buildings to ensure there’s no water leaking into the rest of the building when you’re done.

How to install a mortared shower pan

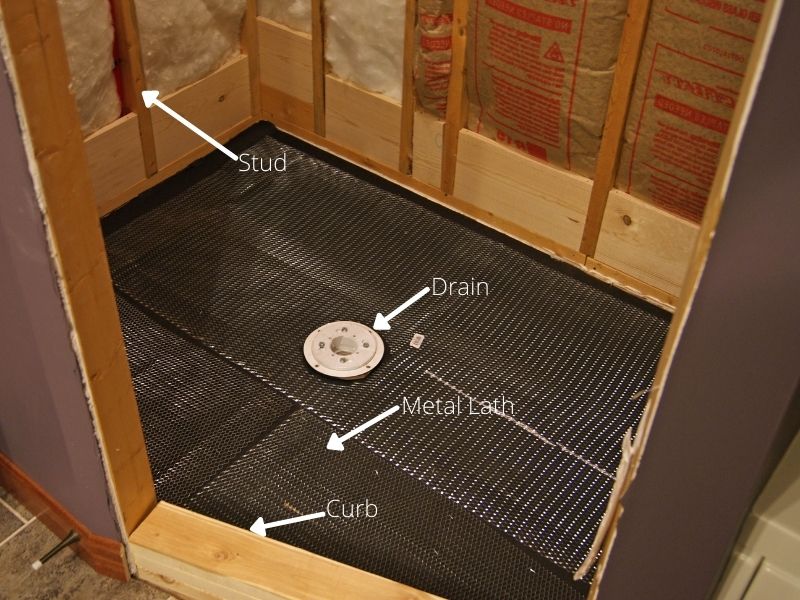

For this exercise, you need premixed mortar, drill, paddle, drill screw attachments, wood screws, bucket, pipe wrench, level, silicone, waterproof membrane, knife, waterproofing membrane, and metal lath. Make sure the plumbing is already carried out, and the shower has a shower drain and a drain trap before installing the shower pan. Your shower needs a P-trap to keep sewer gases out of the house.

Install the mortared shower pan as follows:

1. Frame the shower stall

Choose an area for the new shower stall making sure the drain has been cut out. If the subfloor is shaky, replace it with a ¾-inch exterior plywood. Use pressure-treated wood planks to create the bottom plates for the shower stall.

The studs for the walls should be centered on the bottom plates at intervals of 16 inches. Use 3-inch decking screws to fasten the bottom plates to the floor. Support the sides of the membrane with 2×10 toenail blocking between the studs.

Use 3 pressure-treated planks of wood at 2×4 inches to form the curb of the bathroom.

You can skip this step if you are reinstalling the shower pan in an old bathroom and constructing a new shower pan in a bathroom.

2. Coat the lower side of the drain with silicone

Use silicone beads to coat the inside and outside of the bolt circle of the drain on the floor.

3. Coat the drain with cement and PVC primer

Coat the inside of the drain with cement and a PVC primer, then twist the drain onto the waste line on the floor. After the cement has dried up, insert the drain bolts into the lower drain plate. Leave about ¾ inches of the drain bolts exposed.

4. Cut and fit the metal lath and felt to the floor

Measure the size of the shower floor, then cut a 15-pound piece of felt to fit this size. Place it on the floor, then staple it in place. Using the same measurements, cut a metal lath and staple it on the floor. Make sure there are no bumps on the lath and felt. The metal lath provides a foothold for the mortar mix.

Next, cut a circular hole around the drain hole. The hole should be at least an inch wider than the size of the hole to allow for the next steps.

5. Mix and apply dry deck mud

Follow the instructions on the mortar mix to mix enough for the whole bathroom floor. Use a latex additive to mix the dry deck mud instead of water. Plug the drain hole with a piece of cloth, then pour the mix onto the floor. Evenly spread it out with a wood float, then allow it to dry overnight.

6. Measure and apply the waterproof membrane

Measure the waterproof membrane such that it’s 9 inches larger than the floor on the sides and 16 inches larger on the curb of the bathroom floor. You can make larger pieces of the waterproof membrane by solvent-welding pieces together. The area around the drain should be reinforced by solvent-welding another piece of the membrane on the original one (about 10 inches in diameter).

Lay the membrane onto the floor, smooth out any air bubbles in it, then staple it onto the floor to secure it. Do the same for the excess membrane, parts which will rise up on the wall and curb. Solvent-weld the pieces, then staple them to the wall and curb.

7. Mark and cut out the bolts around the drain

Feel the floor over the membrane, then mark it with an X over each bolt around the drain hole. Use a sharp knife to cut an X over the bolts to expose them. Unscrew the bolts in readiness for installing the upper drain plate.

8. Cut the membrane and install the upper drain plate

Feel the area between the bolts, then cut out the drain hole around the hole and no larger. Place the upper drain plate into the hole, making sure it aligns with the screw holes around it. Screw the bolts to secure the drain plate over the drain hole.

9. Check and fix leaks

Plug the drain hole, fill the shower pan with water 3 inches deep, and wait for 24 hours. If the water level is the same, your pan is watertight. If not, it would have leaked through a loose drain hole, and punctures in the membrane or the sides.

Tighten the drain hole bolts, then fix any punctures using a membrane patch and glue. For the sides of the shower floor, solvent-weld the membrane to the wall, then wait for the solvent to dry up.

Test for leaks again.

10. Install a strainer on the drain

Wrap Teflon tape (plumber’s tape) around the threads of the strainer, then screw it into the drain hole’s flange. Cover it with masking tape to protect it from thinset and mortar in the next steps.

11. Add a waterproof membrane

Apply a waterproof membrane on the wall of the bathroom such that it covers at least 3 inches of the membrane from the floor and parts of the wall.

If the bathroom is made of wooden walls, ensure this waterproof membrane covers the whole wall. A small layer of waterproof membrane is enough for bathrooms with glass or concrete walls.

12. Cut and install the backerboard

Cut backerboard to the size of the walls, then place it on shims ½ inches in size, then fasten the screws to the walls with backerboard screws. The screws should remain at the top inch of the flooring membrane to reduce punctures which may lead to leaks.

Once the backerboard is screwed into place, remove the shims, then fill the areas at the bottom with caulk and thinset.

13. Apply mortar and a metal lath

Mark on the walls with a pencil 3 inches from the floor. Measure the distance from the walls to the drain hole, then calculate the slope to ¼ inches for every horizontal foot (1ft). Apply a layer of mortar followed by a metal lath and another layer while maintaining the slope towards the drain.

14. Lay the floor tiles

After the mortar is dry (overnight), scrape off any bumps and imperfections on the floor, then evenly spread a layer of thinset. Press the tiles into the thinset in line with the slope of the bathroom. Smaller tiles are better at conforming to the slope of the bathroom than larger ones. Let the tiles cure overnight, then apply grout between the tiles and around the edges where the tiles meet the walls.

After the grout dries, install the shower panel and other parts as required. Learn how to clean a shower stall to keep it in good shape.