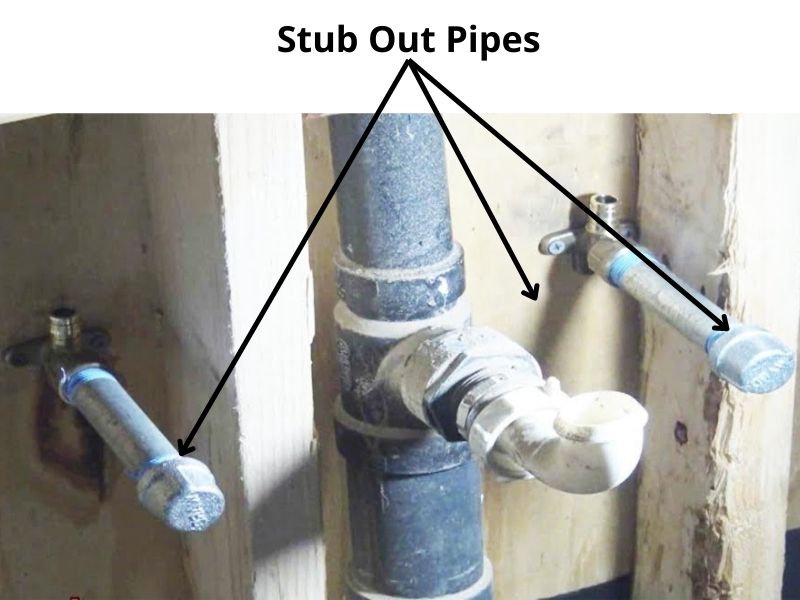

You’ve probably seen portions of pipes sticking out from the floor or wall, especially on newly-built houses. Well, those are stub-out pipes. Pipes carry water, electricity, or gas to our homes. When the electricians or plumbers fix the pipes underground or behind walls, they leave pipe ends sticking out. These stub-out pipes are connected to gas appliances, faucets, or other fixtures during water, gas, or electrical installation.

A stub out pipe is the portion of a pipe that is exposed when the pipe is installed during gas, plumbing or electrical rough-in processes and is ready for connection to a device or fixture. Since there are waste and water supply pipes, the main types of stub out pipes are supply and drain stub outs.

Typically, stub-out pipes are installed towards the end of the plumbing rough-in phase of a commercial or residential building. Most pipe parts are covered during this phase, and the wall is completed and painted. However, the pipe endings must be left to make it possible to connect the plumbing fixtures.

In this guide, we shall look at the types of stub-outs and how to install them. More so, we shall guide you on how to connect stub-out pipes in the finishing phase.

What is a stub out pipe? Stub out meaning

A stub out pipe, also called a pipe out, is the portion of a pipe that is exposed when the pipe is installed during gas, plumbing, or electrical rough-in processes and is ready for connection to a device or fixture. They come out of plumbing walls and can be seen as sealed-off pipe endings.

There are different types of stub outs depending on the type of fixture intended to be fixed to the house. While installing a stub out is easy, it requires knowledge of the slope needed, material, and other aspects which in turn may require the input of an expert. the type of sub out pipe also depends on the plumbing wall thickness.

Types of Stub-Outs

While constructing a building, two types of plumbing pipes are used; the waste and water supply pipes. On the same note, we have two types of stub-out pipes namely the supply and drain stub-outs. Let’s look at each one of them:

1. Supply Stub-Outs

Most houses use ¾-inch copper pipes that act as the main water lines. This waterline supplies water from the main water valve to the heater then branches into two water lines. These water lines carry cold or hot water throughout the building and are fixed behind the walls.

Plumbers fix ½-inch pipes from the ¾-inch water supply and branch them into the intended areas to further supply water into different points. Typically, the ½-inch branch line will be sticking out from the wall or floor to about two inches to enable the plumbing fixture to be installed.

The plumber will fix a cap on the pipe to close the pipe sticking out. However, this cap is cut before installing the fixture. These capped pipes are referred to as supply stub-outs.

2. Drain Stub-Outs

The soil stack, which is the main component of the drain-waste-vent system, takes all waste to the sewer. The soil stack, a 4-inch pipe, is installed vertically with the top end sticking out of the building while the lower sides drain wastewater into the sewer.

All plumbing fixtures carrying wastewater from sinks and toilets connect to the soil stack. Most toilet waste lines are 3-inch pipes. Plumbers usually use PVC or ABS plastic pipes measuring 2 inches in diameter to make fixture drains. Next, they leave one end sticking out of the wall/floor or under the sink and cap it. The capped pipe is referred to as the drain stub-out.

How to Install a Supply Stub-Out

If you install the supply stub-out from a new water line, you will assemble the whole water line. To do this, follow these steps:

- Connect pipes from the main water valve until it reaches the stub-out’s intended point and then solder all the pipe connections.

- Next, install a reducing tee (½-inch from the ¾-inch pipe) near the point of stub-out.

- Connect the pipe to stick out, and cap it to make the supply stub-out.

If you install the supply stub-out from a functioning water line, you must turn off the water using the main valve, drain the pipe, then install the stub-out.

How to Install a Waste Stub-Out

Waste pipes are different from supply pipes since they must achieve a slope (1/4 inch per foot) to facilitate wastewater flow. More so, the tees and elbows in the waste pipes must have sweeps for easy flow of wastewater. The pipe connects to the soil stack that should be vertically installed to vent air and drain waste into the sewer.

Fixture waste wipes require venting, and if the soil stack is very far, you will use another pipe that will rise and connect to the main vent. The plumbing code will guide you on the pipe size and distance from the stub-out when sticking out the fixture waste pipe. If you are stuck, seek professional advice from a plumber.

Include the cost of a waste stub out in the cost of installing a shower base since both costs are to be incurred in the construction of the shower base.

How to Rough-in a Stub-Out Pipe

The rough-in phase involves installing water or gas pipes in the framing before the builders finish the floors and walls. After installing the electrical conduits and pipes, the walls and floor are finished, covering the pipes but leaving the stub-out pipes protruding inches away from the floor/wall.

You must ensure that the stub-out is strategically positioned near the fixtures you wish to connect to them. The rough-in process entails:

- Connecting pipes through the cavities of the walls.

- Installing check valves.

- Installing vent pipes via the wall to connect with the vent stack.

- Connecting the waste pipe and soil stack to the sewer.

- Installing all required fixtures such as water shut-off valves.

After the rough-in phase, the new construction or remodel will have supply stub-outs for taps, showers, sinks, toilets, bathtubs, etc. Additionally, there will be drain stub-out for toilets, sinks, etc.

How to Connect Stub-Outs in the Finishing Phase

Stub-outs should be long enough to ensure that all water pipes are connected to their shut-off valves before connecting them to the toilet or faucet. It is recommended that the stub-outs be between 3-6 inches. The length allows plumbers to cut the stub-out to the preferred length rather than lengthen a short stub-out.

Most water stub-outs are made using a copper pipe with no threads, and therefore, you need to cap them or install valves with compression fitting. If you use valves, the stab out must be more than 2 inches long.

Sinks have two water stub-outs and one drain stub-out coming out of the wall or floor. On the other hand, drain stub-outs for bathtubs, toilets, or showers are 6-10 inches long, protruding from the concrete slab. Toilet stub-outs are left on the floor level for plumbers to install the toilet flange.

When dne with installing and roughing-in the stub out pipes, you can cover them up with tiles and use grout pens between the tiles for a look of your desire.

Are All Stub-Outs Connected?

Not all stub-outs are connected to plumbing fixtures. Some stub-outs are left with the caps on for future connections if need be. For instance, waste pipes draining wastewater from the building to the septic tank/sewer have a stub-out with a removable cap for cleanout operations. More so, the gray water collection system has stub-outs that aren’t connected to facilitate future installations.

Our Verdict

Plumbing, gas pipes, and electricity conduits require skills and knowledge to ensure perfect results. One of the key skills is installing stub-out pipes that finish the final plumbing operations. In general, stub out plumbing helps avoid breaking down a wall to install a fixture in the home. If you intend to add stub out pipes to your building and you can’t do it yourself, you need to enlist the skills of a professional plumber.